[REVOTE] VP16: Funding of Tattva - Carbon-negative biomaterials for modernizing industry

Due to not reaching quorum (enough votes) in the previous proposal, we're reissuing this governance proposal under a 48h voting period. Make sure to vote!

Non-Technical TLDR

Approve a £50,000 (≈$67,000) equity investment in Tattva at a £4,500,000 (≈$6,050,000) post money valuation, plus a partnership to launch an IPToken on Bio Protocol and release a consumer biotech product or art piece made from Stromate.

Construction makes about 37 percent of global emissions. Stromate is a photosynthetic biomineral grown in about 7 days that turns ambient CO2 into structural material; roughly 4 m³ lock in about 1 tonne of CO2. Tests indicate performance consistent with Euroclass A1 noncombustibility, suitable for rigid insulation, structural cores and lintels. Traction includes €450k from G Force, about £925k Innovate UK grant, pre pilot scale with about 60 percent lower unit cost, and trials with Catnic, Voorbij Prefab and Studio biocene, plus 9 partner discussions toward LOIs. The roadmap targets pilot operations in 2026 with high value B2B pilots and initial B2C sales.

This proposal seeks approval to invest £50,000(≈$67,000) into the UK-based constructional biomaterials startup Tattva in return for equity in the company at a post-money valuation of £4,500,000 (≈$6,050,000)

As part of this investment, ValleyDAO and Tattva will enter a partnership to launch an IPToken on Bio Protocol to develop and release a consumer biotech product/art-piece made by Tattva’s Stromate material. An early prototype can be seen here.

Background and Problem

Construction is responsible for roughly 37 percent of global emissions and conventional materials like concrete and plastics drive a large share of industrial CO2 output. Due to increased regulatory pressure and industrial decarbonization efforts, the demand from this sector for low carbon, fire safe alternatives that fit existing codes, workflows, and supply chains has increased. Tattva develops carbon negative, non combustible biomaterials that can be configured as structural cores, rigid insulation, and engineered aggregates. These drop in formats aim to cut embodied carbon, improve life safety, and create value for manufacturers and builders without major retooling.

Technology and Solution

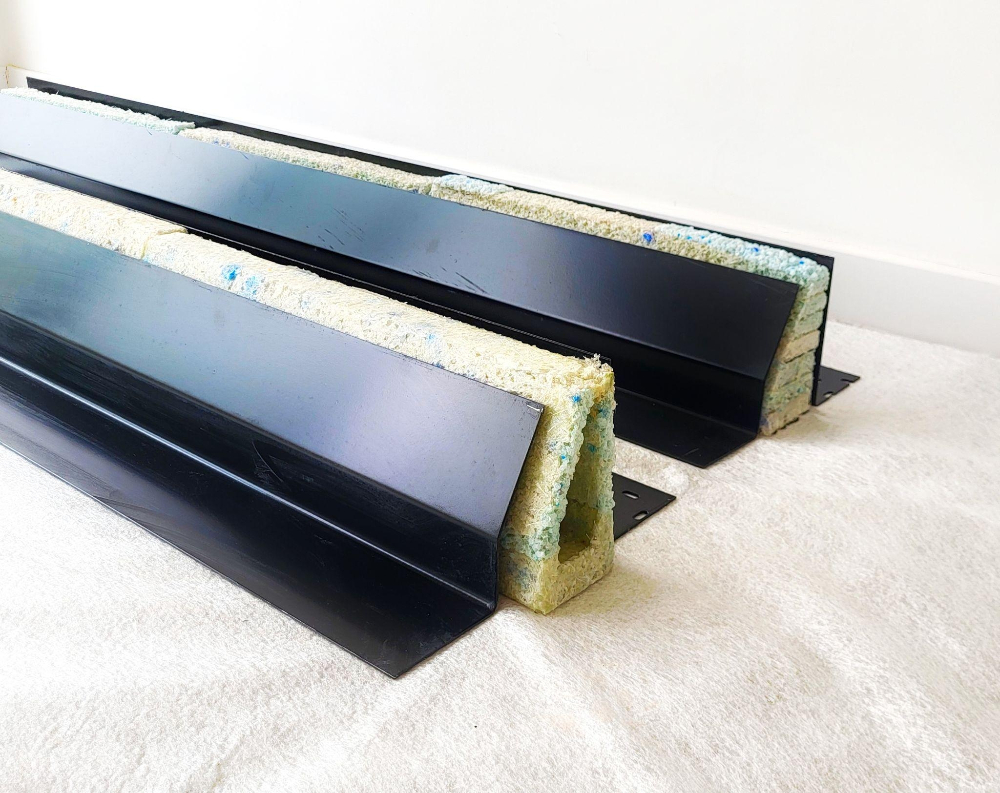

Tattva’s core material is Stromate, a photosynthetic biomineral produced by a solid state cyanobacterial process that converts ambient CO2 into mineralized, structural matter in about seven days. Four cubic metres of Stromate sequesters roughly one tonne of CO2. Independent tests report thermal conductivity around 0.03 to 0.035 W per mK and calorimetry consistent with Euroclass A1 noncombustibility criteria, which means the material behaves as effectively noncombustible, will not contribute to fire growth, and is therefore suitable for use where strict fire safety is required, for example external cladding, rigid insulation cores and lintels. The global insulation market was about USD 67 billion in 2024, with forecasts to roughly USD 87 billion by 2027.

Tattvite is the product family and market-facing brand built from Stromate. While Stromate names the technical, testable biomaterial used in lab, IP and certification work, Tattvite denotes finished SKUs and design-led variants tuned for appearance, form factor and application specific requirements.

Alongside Tattvite, Tattva is building Aureus, an AI platform that learns from lab data to optimize strains, reactors, and product outputs specifically for Tattva's bioprocess.

Timeline and Traction To-Date

TRL = Technology Readiness Level, a measure of the maturity of a technology. Learn more here.

TRL 1: Research initiation (2019). Cyanobacteria growth behaviour studies were initiated.

TRL 2: Technology discovery (2020). A solid-state biomanufacturing process for cyanobacteria was discovered by adapting artificial tissue engineering techniques from mammalian cell culture.

TRL 3: Proof of concept (2021). The first meso-scale proof of concept was grown with support from the British Phycological Society Manton Prize.

TRL 4: Lab validation (2022 to 2023).

-

Funding for Prantar Tamuli’s PhD (CEO) was secured

-

Extensive experiments validated carbon sequestration performance while defining key process control parameters.

TRL 5: De-risking (2024 to 2025).

-

Tattva was incorporated, and first venture investment from G-Force of €450,000

-

Won the Innovate UK Smart Grant granting Tattva ~£925,000

-

Technical and commercial de-risking over 18 months included genome sequencing, fire testing, insulation performance testing, and production process optimization to translate from lab to industrial settings.

-

Scaled-up from lab to pre-pilot, delivering about 60 percent lower unit costs.

-

Customer engagement and trials validated needs and informed product market fit.

-

Catnic from Tata Steel Group - Rigid fire-resistant insulation for pre-fab lintels

-

Voorbij Prefab from TBI group - Granular Stromate (Tattvite for as carbon carbon-negative sand alternative for concrete:

-

Studio biocene - Multi-functional living facade system for Bioscope pavilion:

-

-

Active conversations converging towards signed LOIs: 9 engagements. These include: TBI, Dyckerhoff, Atelier Ten, Foster + Partners, Eden Project, Saint-Gobain, Jaguar Land Rover, Low Carbon Estates / Jeremy Miller, Atiks Realis, Portkabin,

-

Team

Prantar Tamuli, founder and CEO, combines trained architectural practice with advanced biochemical engineering. He invented Tattva’s solid-state cyanobacterial process during his PhD at UCL, won the Manton prize for his research, and brings a rare ability to design material form and assembly that meets construction workflows and regulatory needs.

Andrew Gray, cofounder and COO, is a hands-on operator with 25+ years running large scale farming, quarry and processing operations. His experience leading Elston Farm and related enterprises provides practical site infrastructure, production management and supply chain know-how that derisks pilot hosting and on-farm manufacturing.

Dr Steven Roberts, cofounder and commercial lead, is an experienced executive and operator with decades in senior roles at Barclays and as founder of Eagle Labs. He leads commercial strategy, partnerships and investor relations, translating technical milestones into market and funding outcomes.

Jeremy Miller, chief engineer and technical advisor, is a seasoned process engineer with leadership roles across industrial gases and engineered systems and a proven patent track record of 150+ patents. He drives reactor design, thermal and energy management and scale engineering to turn lab methods into reproducible, certifiable production.

Research and Business Development Roadmap

-

2025 Q3-Q4

-

Conduct technical and economic feasibility tests of Green sand/granular stromate application

-

Develop continued customer relationships for further sales and R&D trials

-

Establish construction of Pilot plant room

-

-

2026 Q1-Q2

-

Establish collaborations and apply for ARIA and EU grant

-

Establish pilot plant foundation and initiate operations

-

Narrow down on the target beachhead segment for continuous pilot operations.

-

Initiate B2C consumer product goals and design

-

Initiate seed fundraising round.

-

-

2026 Q3-Q4

-

Initiate continuous pilot trials.

-

Execute B2B high value pilot project.

-

Execute B2C sales

-

Close fundraising round.

-

Off-Chain Vote

Timeline

Sep 22, 2025Proposal created

Sep 22, 2025Proposal vote started

Sep 24, 2025Proposal vote ended

Sep 24, 2025Proposal updated